Quality control & Productivity

The strategy for assurance of quality, hygiene and food safety of our products as well as of our production units represents our greatest concern and one of the most important factors for the success of our activity so far. For us, the assurance of quality is not just excellency, it is a guarantee for meeting our commitments to the consumers.

The use of basic material from acknowledged suppliers observing the highest quality standards responds to the market demands, namely to the making of high quality products.

We track and check every step of the production process under the guidance of our Quality Inspectors and of the Laboratory Assistants. The unit has a laboratory endowed with equipment of the last generation meant for physical, chemical and organoleptical analysis, thus guaranteeing an end product handed to the customer in a perfect shape and observing the in force requirements of the European and national standards and regulations. Our products are analyzed periodically by a Renar accredited laboratory. .

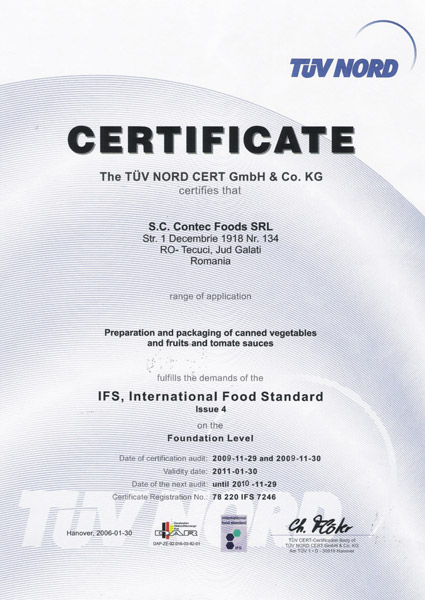

Since 2004 we have implemented the system of quality insurance and food safety in accordance with the German I.F.S (International Food Standard), and the certification took place in November 2005. The IFS observes the ISO 9001: 2000 requirements, the HACCP standards which are comprised in ISO 2200:2005 as well as an additional set of requirements concerning a product. The control and certification audits are applied by TÜV NORD Romania in accordance with the procedures of TÜV NORD CERT and the issuance of the certificate is made by TÜV NORD CERT, Germany.

The main priorities in the management of the organization are as follows:

- A continuous development and implementation of the infrastructure of the organization;

- The involvement of the whole staff in the continuous improvement actions for the quality of our products;

- The improvement of working conditions;

- A steady improvement of the technical capability used in the making process of the product;;

- The increase of the proficiency level for the execution staff;

- The identification, evaluation and keeping under control of all risks able to compromise product’s food safety;

- Making the whole staff become aware of the importance of implementation and application of the standards of Good Production Practice and Good Hygienic Practices;

- Making the whole staff become aware of the importance of the observance of the Good Production Practice and Good Hygienic Practices;

- The implementation, maintenance and continuous improvement of the system of quality insurance and food safety (IFS);

- Protecting the environment.

The quality assurance system provides objective evidence and example for the fact that our products meet the most exigent culinary requests and needs of our clients, as well as for the assurance of their safety.